FlexLink Case Study: Not just a Platform, a Partnership

In this case study, we explore how FlexLink, a Sweden-based manufacturer of flexible, modular conveyors and industrial automation equipment, partnered with Visual Components to turn their vision for a 3D design and visualization tool into a reality.

Flexlink is a Gothenburg, Sweden, based manufacturer of flexible, modular conveyors and industrial automation equipment. Founded in 1980 and part of the Coesia Group since 2012, FlexLink today has more than 1,100 employees with operating units in 27 countries.

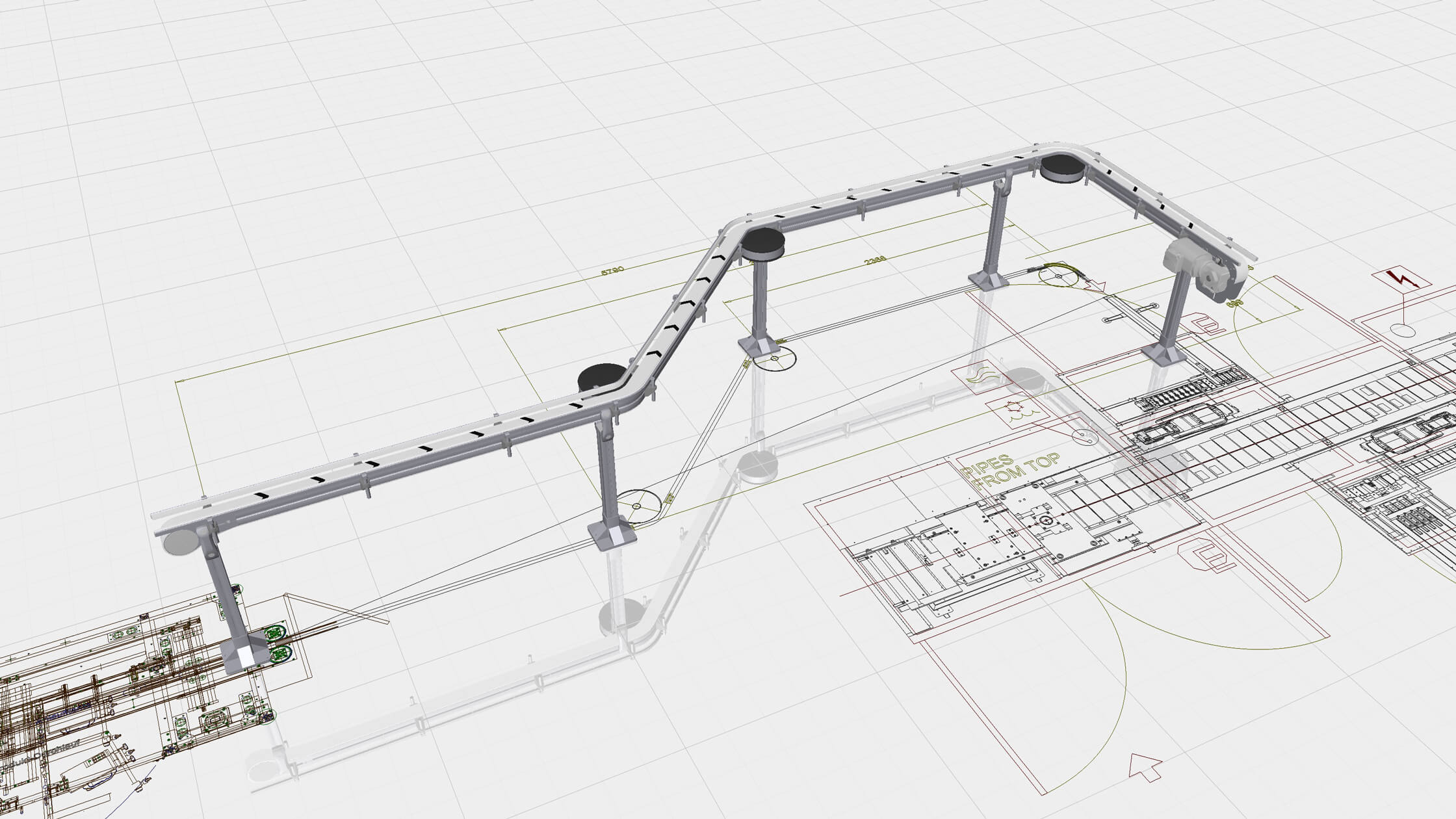

In 2013, FlexLink initiated a search for a partner to support the development of a new visualization tool, which would become the FlexLink Design Tool. Following an extensive evaluation, FlexLink selected Visual Components to utilize their 3D manufacturing simulation platform. In this case study, we explore the history of this partnership, FlexLink’s vision for the FlexLink Design Tool, and how this vision became a reality with Visual Components.

Further reading

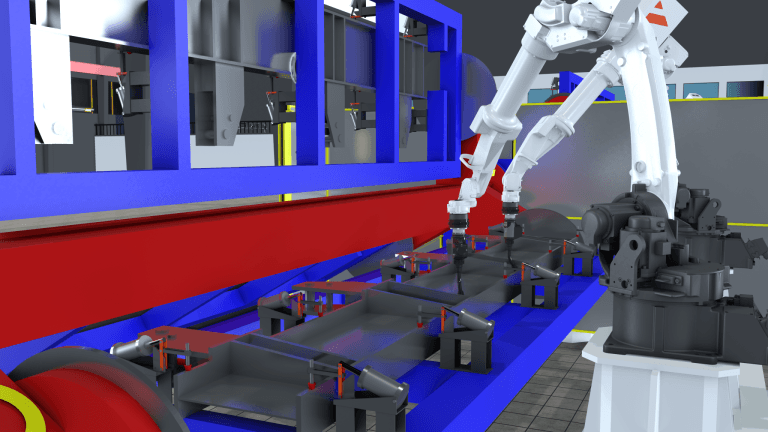

Mastering complex welding: Bunorm Maschinenbau’s quality and efficiency boost with Visual Components OLP

Bunorm Maschinenbau, a full-service supplier known for complex welding solutions, is committed to maintaining a high level of modernization and flexibility of their infrastructure. With their wide-ranging capabilities, the focus...

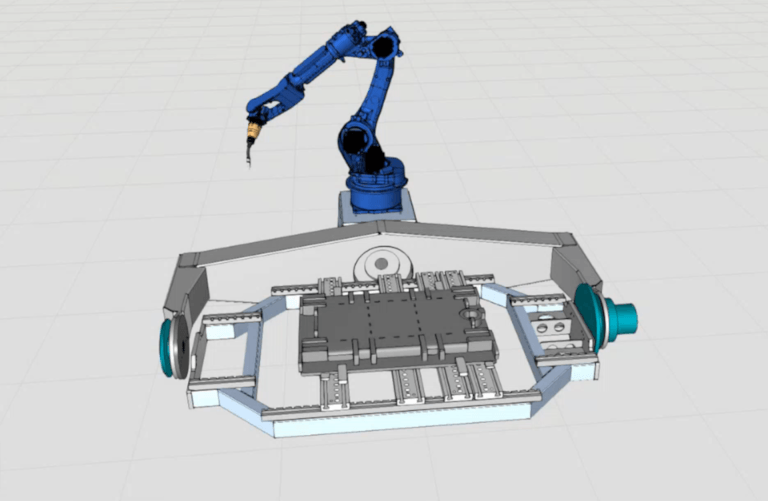

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

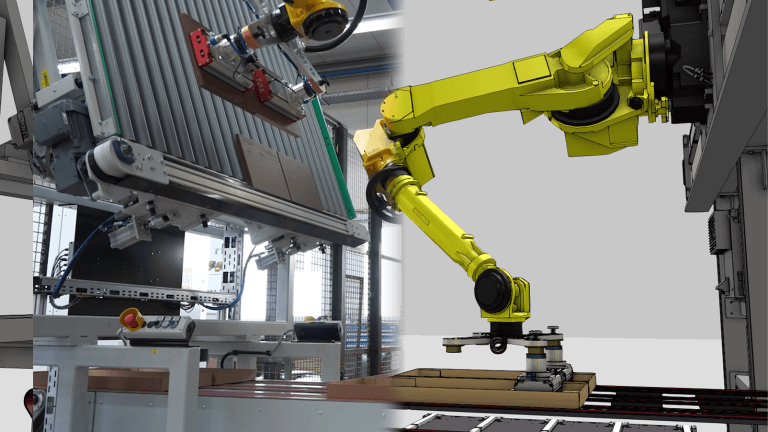

Packaging perfection: navigating variations in furniture packaging with Visual Components

The furniture industry has shifted from handcrafted pieces to mass-produced, self-assembly models made from materials like MDF or chipboard. This change has complicated packaging due to the need for high-volume...